The pandemic certainly changed the way many organizations approach cleaning and disinfecting, and reading chemical labels is vital. Facilities of all types are using disinfectants more frequently, thus increasing the chance that products are used without proper oversight. Failing to thoroughly read a chemical label can often result in an incorrect application, which can put cleaning professionals, building occupants, and the environment at risk. This makes following label instructions correctly more important than ever.

How to know if a disinfectant is effective

If a manufacturer offers a solution that is intended to inactivate a virus, the Environmental Protection Agency (EPA) must be aware. In addition, manufacturers of devices that create a disinfectant (like on-site generation systems) or those that are used with disinfectants (like electrostatic sprayers) should be able to provide sufficient proof that the device has been tested against the virus it claims to inactivate. Manufacturers should also have proof that they produce the devices in an EPA-approved facility.

Meanwhile, bottled solution manufacturers should be registered and have their EPA registration number printed on the product label.

There is strict regulation on what can and cannot be put on a bottle’s label. Every claim on the label, from target organisms to container disposal directions to marketing claims is thoroughly reviewed. This process is essential for securing an EPA registration number for a product label.

How can you identify whether a product is registered by reading the label? Look for the EPA registration number and the EPA establishment number. This is typically listed on the back panel of the label near the manufacturer’s name and address.

Optimize cleaning and disinfection protocols

Once you’ve confirmed the product is registered, the next step is to understand its proper application. Chemical labels should have a distinct section titled “Directions for Use.” The following legally required disclaimer is an important requirement of this section “It is a violation of federal law to use this product in a manner inconsistent with the label.”

The “Directions for Use” section will detail how to wipe, spray, or fog the product. Remember, if a certain application method is not listed, it cannot be used. For instance, the EPA now requires specific testing for fogging and electrostatic spraying claims. If there are no instructions for it, by law, the product cannot be applied in that manner. Doing so may lead to safety, performance, and sustainability issues.

Other important information also found in the “Directions for Use” section includes:

- Whether precleaning is necessary

- Contact time

- Types of surfaces that can be disinfected

- Target organisms the product is proven to be effective against

Minimize risks by identifying potential hazards

As all disinfectants are intended to destroy harmful living organisms in one form or another, the idea that any one formula is “safe” is not accepted. Words like “safe” or comparisons to other formulations as “safer” are not allowed when registering a product. A disinfectant label is not for marketing purposes – it is meant to communicate any hazards on chemical labels that the user may be exposed to, and detail how to minimize risk.

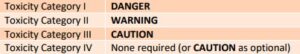

If a product has a known hazard, it must be communicated via a “signal word” on the label’s front panel. Based on strict criteria for the five routes of exposure (as defined in 40 CRF 156.62), a disinfectant can fall into one of four categories based on the toxicity level (see Table 1).

Table 1: Excerpt from the EPA label review manual stating the required signal words for the respective toxicity category.

Category I is the highest toxicity category and Category IV is the lowest. Each category requires a specific signal word. If no signal word is listed on the label, the product has met the criteria for category IV, or the lowest toxicity category.

Making the most of disinfectants

Cleaning professionals should make the most efficient use of disinfecting chemicals, following each label and device’s directions. It is equally essential that facility managers and their teams remember that what appears on a bottled solution’s label or in a device’s instruction manual is just as important as what does not appear there. With the proper understanding of disinfectant efficacy, protocols, and risks, organizations can enhance cleaning performance, sustainability, and safety, which is key for preventing and reducing the impact of future SARS-CoV-2 outbreaks.

Tyler Williams is director of Scientific Services at PathoSans, a leading provider of on-site generation (OSG) devices that produce ready-to-use, highly effective, sustainable cleaners and sanitizers known as electrochemically activated (ECA) solutions. To learn more about PathoSans, visit www.pathosans.com.